Accelerating the Future

HNTB and Florida’s Turnpike Enterprise created SunTrax, America’s

next proving ground for transportation technology innovation

DESIGNER

2020

If you want to be a part of the future of transportation, make plans to be in Central Florida in 2021. That’s when Florida’s Turnpike Enterprise will open the second phase of SunTrax, a 475-acre toll equipment and autonomous and connected vehicle testing laboratory dedicated to developing and testing emerging transportation technologies.

“As the world’s first test facility that is purpose-built for developing tolling and connected and automated vehicle technologies, SunTrax fills a need for advancing transportation solutions in a safe, efficient and thoughtful way without the same risks of testing on public roads,” said Nicola Liquori, FTE executive director/CEO.

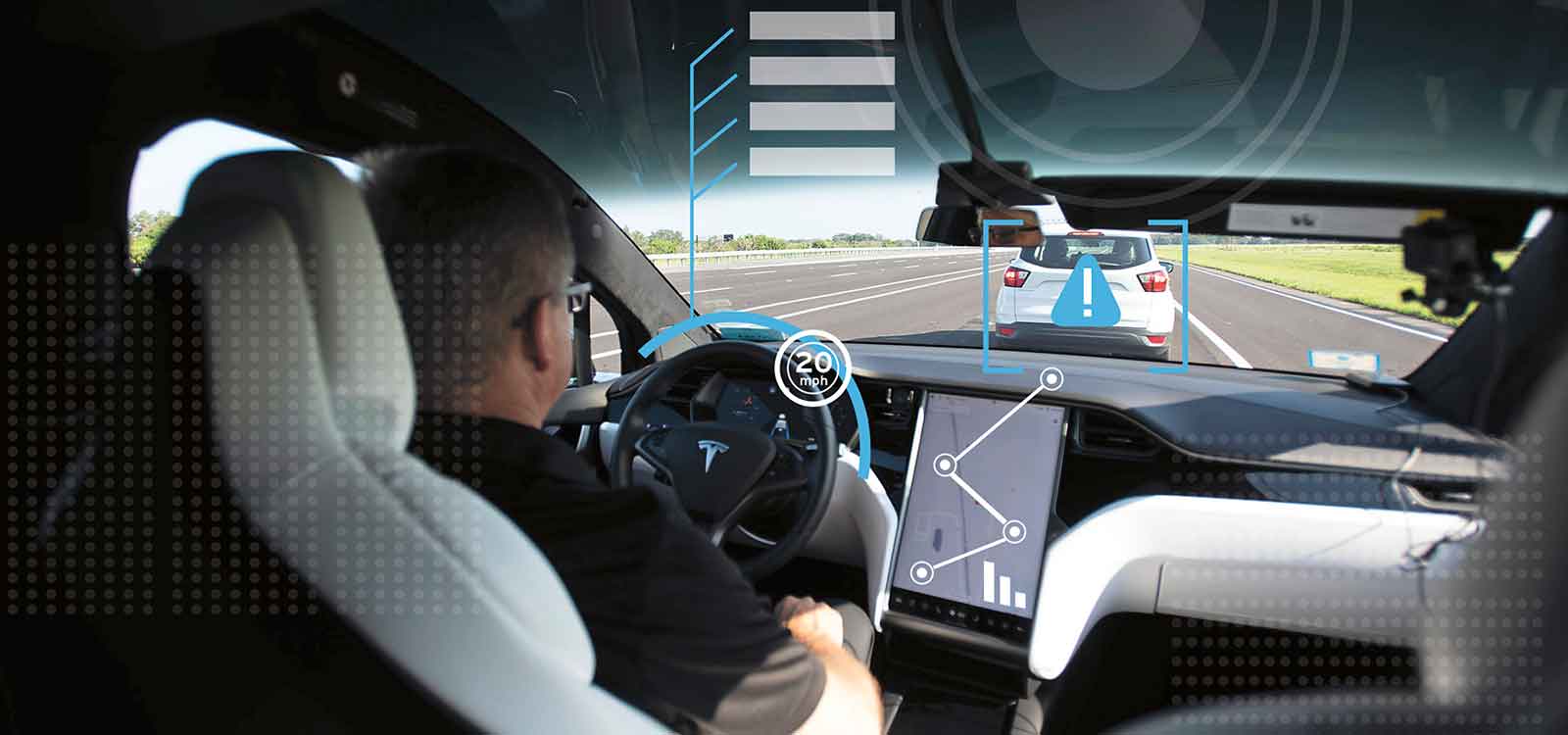

When phase 2 comes online, it will accommodate a variety of users in the CAV space, including auto makers, tech firms developing self-driving systems, tier-one auto equipment manufacturers, freight operators, companies developing mobility as a service and many others. The various transportation environments being constructed at SunTrax have been designed specifically to replicate the diverse edge-case scenarios that are needed to test the vehicle platforms, sensor suites and software builds that must all integrate seamlessly for automated vehicles to work safely.

“SunTrax will help accelerate the U.S. — and the world — into the future of transportation, and it further positions Florida as a leader in the development of advanced mobility solutions by partnering with these leading-edge companies.”

Nicola Liquori, FTE Executive Director/CEO

The fully wireless connected environment at SunTrax also will enable the development of Vehicle-to-Vehicle (V2V), Vehicle-to-Infrastructure (V2I) and Vehicle-to-Everything (V2X) communications systems that are already enabling innovative new ways of managing and operating our Smart Cities and the rest of our transportation network.

FTE has already received interest from companies across the U.S. as well as Europe and Asia.

Toll testing already underway

Initiatives similar to SunTrax are underway in other states, including the American Center for Mobility in Michigan; however, SunTrax is the only testing grounds with a tolling component, according to Mark Beall, FTE director of toll operations.

“Before SunTrax, we were testing toll technology live on our system, and that was impacting our customers,” Beall said.

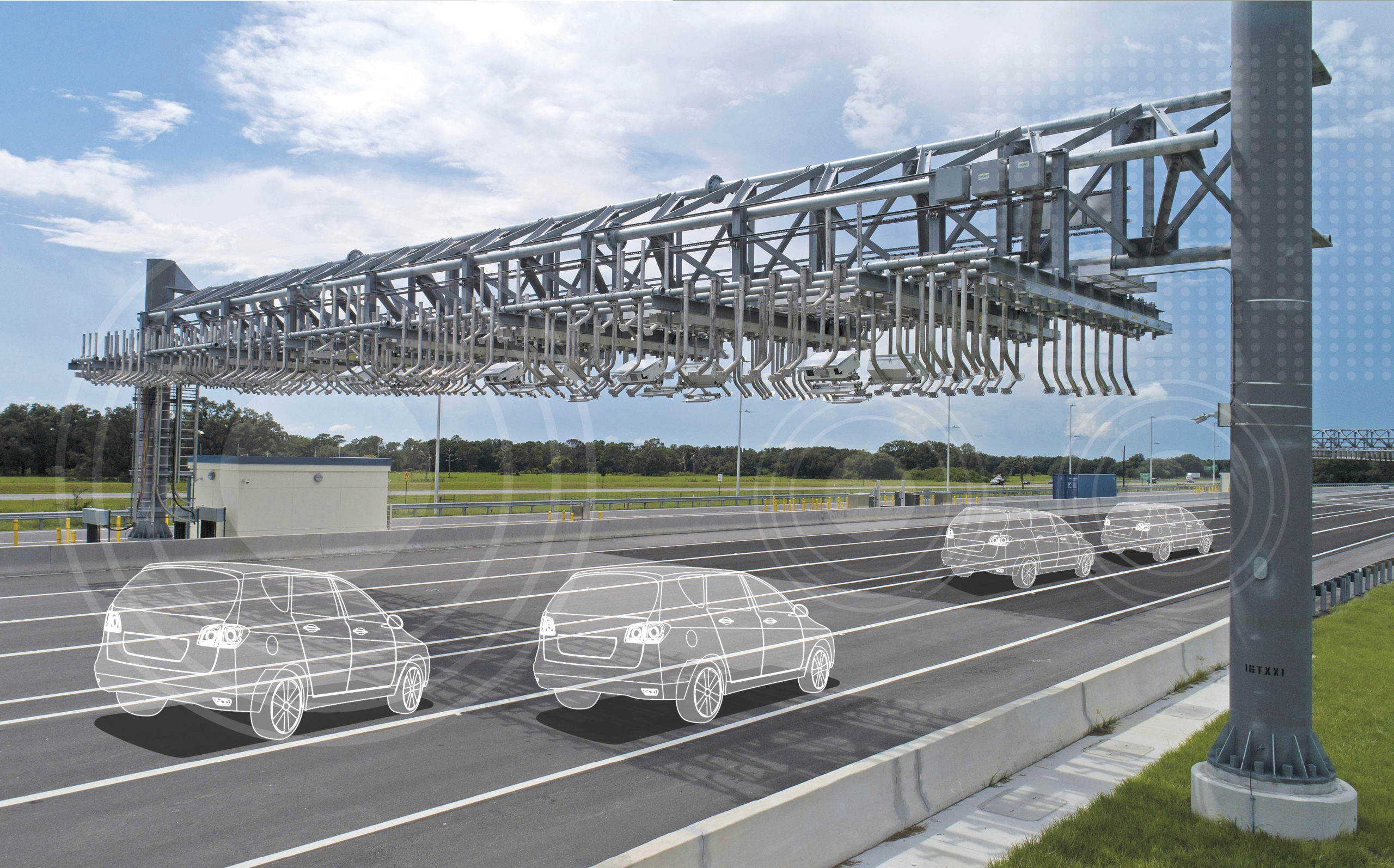

Phase 1 of the SunTrax project was designed to provide FTE an ideal location to perform toll testing and was completed in June 2019. It is now being used by FTE and its tolling technology vendors. The infrastructure built during phase 1 includes a 2.25-mile oval track built to interstate highway standards with a 70-mph speed limit and 10-degree banked turns. The track straightaways contain five lanes that can operate reversibly and two wide shoulders that can be converted into travel lanes. Phase 1 also included two new buildings for FTE staff offices and equipment storage, as well as four free-flow tolling gantries spaced around the track.

“SunTrax now provides us with the perfect environment to test toll equipment, tolling software builds, dynamically managed express lanes and future tolling technologies, so we can continue to provide our customers the highest possible level of service,” Beall said.

The track is available to lease now, but Beall sees more potential. He believes SunTrax could be a future venue for national and international toll-technology certification.

Experience SunTrax

Click here to take a 360-degree virtual tour of

America's center for transportation innovation.

Building out the infield

The oval track — the Southeast’s only highway-speed autonomous vehicle testing facility — is phase 1 of the three-phase project. Phase 2, now under construction, will add nine more simulated transportation environments in the 200-acre infield:

- A main campus entry with a welcome center, offices and classrooms

- Private, air-conditioned workshops and warehouses with high-speed data connections

- Roadway geometry track with manufactured hills, horizontal and vertical curves and a variety of grade changes

- Two continuous loop tracks with entrance and exit ramps to test collision avoidance and maintenance of traffic during active road construction

- An urban setting with multiple intersection configurations, a signalized corridor and moveable shipping container “buildings” to simulate a downtown environment

- A suburban environment with various additional intersection and driveway configurations

- A curbside pick-up and drop-off environment with adjustable lane striping and signing to replicate multimodal passenger transfers at airports, hotels and transit centers

- Braking tracks with low-friction surfaces and various pavement types for vibration, durability and machine vision testing

A 20-acre paved technology pad with enough open space to replicate real-world geometric configurations and enable vehicle-in-the-loop testing of self-driving systems

These infield features will all be completed in 2021. Phase 3 of the project, an enclosed sensor test chamber that will simulate rain, airborne debris, smoke, fog and other environmental challenges, will be constructed separately in another area of the infield. It is scheduled to open in 2024.

SunTrax’s phases 1 and 2 are being funded by FTE toll revenues at an estimated $142 million. Revenue generated from leasing the facility will help recoup capital costs as well as pay for operation and maintenance expenses.

“We wanted to create as many challenging environments as possible, while also maintaining as much flexibility as possible to adjust the types of testing scenarios that can be provided in the future,”

— Paul Satchfield, FTE Program Manager for SunTrax

Delivering the vision

As general engineering consultant/program manager for FTE, HNTB played a key role in bringing world-class thinking and programming to this one-of-a-kind project.

“Assisting FTE every step of the way, HNTB created initial design concepts for the track and the infield, coordinated the entire planning and design process across all project phases, managed multiple design firms, performed technical quality assurance/quality control reviews on all design submittals, and assisted FTE with branding and marketing of the facility,” said Josh Pedersen, HNTB project manager.

Planning phase 2 was where HNTB’s depth and breadth of services and industry connections really paid off.

“We wanted to ensure the facility would operate efficiently, provide an excellent user experience and be safe and secure enough for a diverse user-base whose products could be highly proprietary,” Pedersen said.

Planning required a great deal of research, industry outreach and analysis to determine those testing features that would be most valuable and attractive to future users.

“We built and leveraged connections with automotive proving grounds and companies working all across the CAV landscape to help FTE determine the facility’s composition,” Pedersen said.

As program manager for the design of phases 1 and 2, HNTB also has enlisted expertise from multiple disciplines inside the firm, including tolling, program management, ITS, traffic, emerging technologies, sports architecture, graphics/schematics, government relations and traditional highway design.

“We managed the delivery of phase 1 design plans in just over a year,” Pedersen said. “Then we completed both the master planning and the final design of the much more complex phase 2 in just two more years.”

To accelerate the timeline, HNTB brought in a dedicated project strike team to perform design submittal reviews and develop a streamlined planning process using project-specific scheduling and review tools.

“HNTB’s contributions to the planning and design process, their ability to connect us to the right industry experts, and their assistance with the management of this unique and complex program have allowed us to create the facility we envisioned,” Satchfield said.

Other key project decisions included determining the project’s delivery method, the overall business model and organizational structure.”

The companies with the right experience to successfully operate the facility turned out not to be best suited to also perform construction of the facility. So we delivered the project with a traditional design-bid-build model and developed a separate long-term concession agreement to procure an operator,” Pedersen said.

HNTB assisted with developing all the contract documents and coordinated operator procurement on behalf of FTE. The operator will perform day-to-day operations, facility maintenance, sales, marketing and business development functions.

A united front

In 2016, the USDOT released an RFP for U.S. Department of Transportation-designated autonomous vehicle testing grounds. From more than 60 applicants, 10 locations were selected. One was Central Florida.

Key to the selection was the coalition backing SunTrax. Heavy-hitting sponsors include the FTE, FDOT, LYNX, Central Florida’s bus system, the City of Orlando, the Central Florida Expressway Authority, NASA’s Kennedy Space Center, the Florida Agricultural and Mechanical University-Florida State University, Florida Polytechnic and the University of Central Florida. Together, they are taking a comprehensive approach to developing and deploying emerging mobility solutions across Central Florida.

The partnership, known as the Central Florida Automated Vehicle Partners, provides three necessary components: simulation at the university partners, closed testing at SunTrax and eventually open-road deployments on public roads.

An economic accelerator

Conditions are ripe for the CAV industry to explode in Central Florida. SunTrax is designed to be a catalyst for economic growth in the region, attracting a large slice of the estimated $7 trillion autonomous vehicles are expected to generate by 2050.

Polk County officials, where SunTrax is located, point to the abundance of vacant land near SunTrax, calling it a prime location for users to build individual testing locations, permanent office space and warehouses. The cities of Auburndale and Lakeland are teaming with an economic development organization to promote technology-oriented growth around Florida Polytechnic University and the SunTrax facility. The two cities unanimously approved memorandums of understanding with the Central Florida Development Council in September 2019 to endorse the creation of the Central Florida Innovation District.

Located off Interstate 4 between Orlando and Tampa, SunTrax is conveniently located near FTE headquarters, the Polk Parkway and Florida Polytechnic University, a STEM-focused university that brings exciting research partnership opportunities.

“Between SunTrax infrastructure and FTE’s partnership with Florida Polytechnic University and the university’s new Advanced Mobility Institute, we expect to attract economic development and a significant number of high-tech jobs to the region,” Liquori said.

“This is exactly how other big research parks across the country and the world have been developed,” Pedersen said. “SunTrax can be the catalyst that makes this area the next hub for transportation technology development.”

SEE MORE ARTICLES

US 290 Program

INDYGO RED LINE

CASEY ARBORWAY

ALLEGIANT STADIUM

CHAMP CLARK BRIDGE

ORLANDO INTERNATIONAL AIRPORT, SOUTH TERMINAL