Replacing the Champ

HNTB’s low-maintenance, straightforward design gives a rural bistate community

a wider, safer Mississippi River crossing

DESIGNER

2021

In 1928, HNTB’s predecessor company designed the original Champ Clark Bridge, spanning the Mississippi River. Nearly 100 years later, when the bridge was functionally obsolete and in poor condition, HNTB returned to the site to design a replacement.

The original five-span truss bridge, named after James Beauchamp Clark, a former Missouri state official, carried U.S. Highway 54 over the river and connected Louisiana, Missouri, with Pittsfield, Illinois. At 20-feet-wide, and without shoulders, the two-lane bridge seemed to have shrunk over the years as the size of vehicles grew. To ensure there was enough room to safely cross the bridge, farmers and truckers with large loads would pull off the road, call local law enforcement and wait for them to arrive. The responding officer or deputy would shut down one lane of the bridge to normal traffic, escort the vehicle across and then reopen the bridge.

“That happened about 20 times a month,” said Keith Killen, PE, project director for the Missouri Department of Transportation.

Worse, the bridge was the bistate community’s connection to the nearest hospital. Traveling to the next closest bridge, 45 minutes away, could present a life-threatening delay.

By 2017, the bridge carried nearly 4,000 vehicles a day. The narrow roadway, high maintenance costs and frequent flooding of the Illinois approach drove the Missouri and Illinois Departments of Transportation to pursue a replacement.

A winning partnership

In June 2017, the bistate owners awarded Massman Construction Co., a $60 million fixed-cost, variable-scope contract to deliver a new bridge. As Massman’s design subcontractor, HNTB was a crucial part of the design-build team.

HNTB and Massman had partnered on dozens of major river bridge projects. Both firms hoped their easy rapport and familiarity with each other’s problem-solving approach would be viewed as assets to the project. In fact, it helped the team earn a spot on the shortlist.

“The relationship and collaborative nature between HNTB and Massman helped them make it to the final four,” Killen said. “Once they were selected, we could tell they weren’t trying to maximize each other’s profits. They were trying to deliver the best quality product to Missouri and Illinois that they could.”

According to Killen, MoDOT and IDOT wanted a wider, safer bridge — one that would serve the community for the next 100 years, be easy to inspect and easy to maintain.

“Their proposal scored consistently across all of those areas,” he said.

HNTB was responsible for design and design quality assurance and quality control for the new bridge while fulfilling the commitments set forth in the environmental assessment. Missouri and Illinois shared the cost of the new bridge with MoDOT as the project lead.

SEE MORE

Design-build firsts

The design-build procurement was a breakthrough in both states. The MoDOT district, where the western side of the Champ Clark Bridge is located, had never delivered a project via design-build, and IDOT does not have legislative authority to use design-build for public projects. With MoDOT as the lead agency, IDOT was able peek behind the curtain and experience the design-build process. IDOT assisted in selecting the short list, scoring proposals and reviewing roadway plans.

An efficient, value-added design

Because HNTB and Massman had teamed up to deliver on some of this country’s most iconic Mississippi bridges, including the Huey P. Long, Stan Musial, Bill Emerson and U.S. 82 at Greenville, they were able to quickly arrive at a design solution for the Champ Clark Bridge.

“We designed a low-maintenance, straightforward plate girder bridge that more than doubled the traversable width of the previous bridge,” said Hans Hutton, PE, HNTB design manager.

Two 12-foot-wide lanes, with 10-foot-shoulders in each direction, provide ample clearance. And, with the shoulders extending past the bridge onto the east roadway, MoDOT and IDOT received more project than they had expected. It was the first of several value-adds the team brought to the project.

The new bridge includes four river piers, each founded on 11-foot, 6-inch-diameter drilled shafts, with three land piers that incorporate 48-inch-diameter pipe pile foundations and columns.

“The large drilled shafts allowed us to reduce the number of shafts per pier, which saved time and money,” said T.J. Colombatto, Massman project manager.

HNTB worked closely with the U.S. Corps of Engineers on both sides of the river to ensure the bridge design, as well as the temporary construction conditions, met the agency’s no-rise requirement.

“Reducing the number of piers helped us achieve the no-rise conditions,” Hutton said.

The pile foundations for the land piers were not part of MoDOT’s preliminary design, footing foundations were, but the design-build team’s modification saved schedule time and reduced potential flooding risks.

HNTB’s design positioned the land piers to avoid Burlington Railroad right of way, and designers worked with the U.S. Coast Guard to meet restrictions on horizontal and vertical clearances.

“We were very satisfied with the design,” Colombatto said. “It met all the owners’ requirements.”

But the team’s contribution to the area wasn’t finished. Because the new approach on the Illinois side crossed over a levee, HNTB collaborated with the federal levee district to improve the flood barrier.

“Route 54 creates a notch in the Sny Levee, making the roadway unreliable during flood events,” Killen said.

When the roadway floods, it cuts off access to the bridge on the Illinois side. According to Killen, the roadway was shutdown at least 20 days in 2019 due to high water.

“Our design raised the Illinois approach, which will maintain traffic during extreme flood events,” Hutton said.

“It was a key feature of the project,” Killen said, “not only would we have a safer bridge, it would be more reliable.”

Recruiting the future

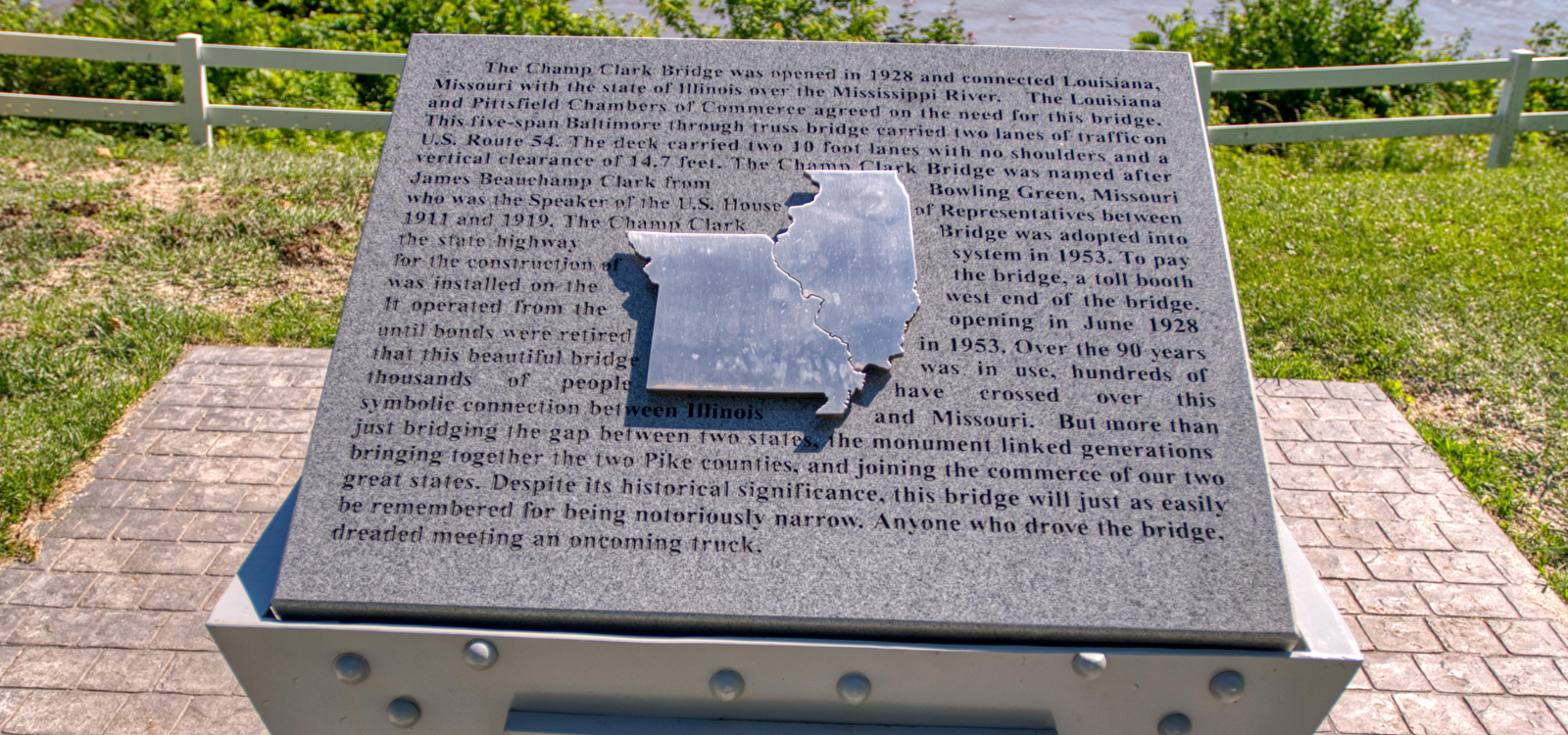

The design-build partners offered a career fair, project site tours and a summer camp for area STEM students. The students also were invited to develop ideas for an interpretive panel commemorating the original bridge. The winning design incorporates pieces of the old truss into the base of the monument that overlooks the bridge in Riverview Park.

HNTB disciplines

- Bridge

- Electrical

- Environmental

- Geotechnical

- Hydrologic

- Roadway

Faster construction, longer life

The 2,288-foot-long bridge is made of five steel girder river spans and three prestressed girder approach spans. HNTB designed the main span and secondary span to be equal lengths, at 420 feet each.

“The secondary span provides a backup navigational channel and reduces obstructions for marine traffic. This was provided as additional value to the owner and stakeholders. It also minimizes the number of piers susceptible to vessel impact and the number of heavy piers to construct,” Hutton said.

To reduce the construction schedule, the main steel unit was decked with 181 precast deck panels. According to Hutton, precast panels, in general, aren’t innovative but their application on this bridge was unique.

A bridge that exceeds expectations

During construction, Massman maintained regional traffic by keeping the existing bridge open and erecting its replacement just 50 feet downstream. The new Champ Clark Bridge opened on time and on budget in August 2019. The structure is expected to serve the region for the next 100 years.

“It’s been a great project,” Killen said. “I’ve received a lot of positive feedback from the community. The wider, safer bridge is meeting their needs and that was the goal. We are extremely happy with the end product.”

Award-winning bridge

The Champ Clark Bridge Replacement project has been recognized by the Design-Build Institute of America, American Council for Engineering Companies of Missouri and Roads & Bridges magazine for its technical excellence and contributions to the community.

Community participation

As part of their plan, HNTB-Massman made a large cut in a hillside adjacent to the Missouri end of the bridge to accommodate a new east-west roadway. To support the hillside, a retaining wall was built that is approximately 10 feet high and 160 feet long. Residents were invited to vote on the wall’s aesthetics. They chose a precast modular block system with a rosemary-colored ledgestone pattern. About 350 people — or 10% of the local population — participated.

SEE MORE ARTICLES

MORE DESIGNER STORIES

INDYGO RED LINE

CASEY ARBORWAY

ALLEGIANT STADIUM

ORLANDO INTERNATIONAL AIRPORT, SOUTH TERMINAL

US 290 Program