Far and Wide

Improving the drive on 405

Design-build delivery accelerates the massive job of widening the nation’s most congested interstate.

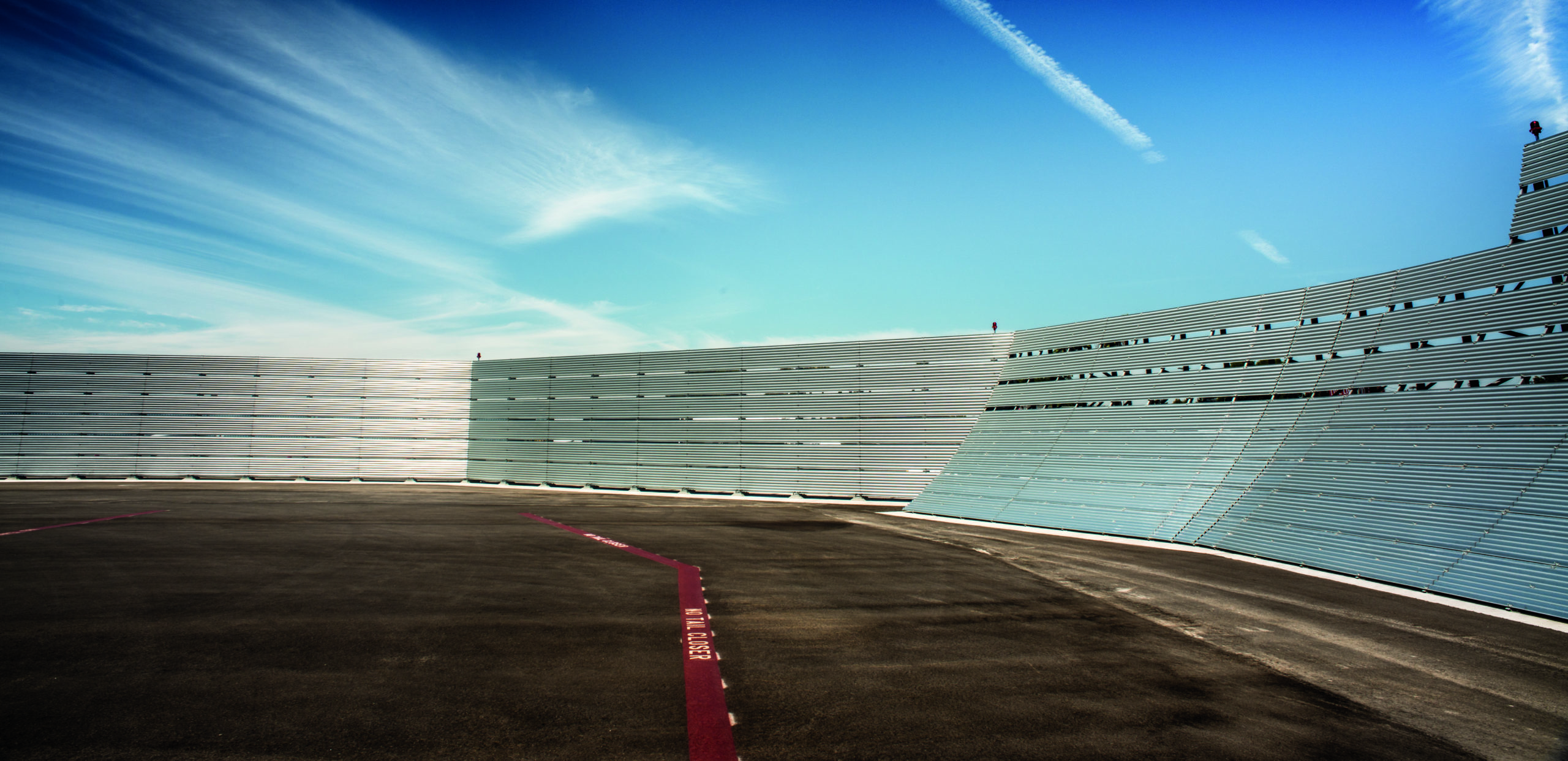

Los Angeles’ Interstate 405, a sprawling 12-lane highway, serves an estimated 379,000 vehicles per day, making it the busiest interstate in any American city. Portions of the facility operate at a deficient level of service for approximately 15 hours a day, creating those iconic images of traffic congestion most associated with L.A. Loosening congestion in those lanes and helping motorists get to their destinations more reliably is the soon-to-be-realized vision of the Los Angeles County Metropolitan Transportation Authority and the California Department of Transportation. Together, they are overseeing delivery of the I-405 Sepulveda Pass Improvements Project, the largest design-build highway improvement project Southern California has ever seen.

10 miles could save 10 minutes

The project’s goal is to add a 10-mile high-occupancy vehicle lane to the northbound side of I-405 between the I-10 and U.S. 101 highways, completing the last gap of carpool lanes along 72 miles of the 405.

The additional HOV lane has the ability to carry 2,000 vehicles per hour and shorten northbound commutes by 10 minutes a day. Other improvements include adding standard lane widths and shoulders—something the 405 lost as it was widened over the years — to enhance traffic safety and operations.

The design-build team of Kiewit Infrastructure West and HNTB Corporation was selected in February 2009 to implement the massive project. By that summer, final design activities were underway with deliverables that included:

• Removing and replacing three bridges

• Realigning 27 on- and off-ramps

• Fully reconstructing seven interchanges

• Widening 20 existing undercrossings

• Constructing approximately 12 miles of retaining walls and sound walls

• Realigning portions of Sepulveda Boulevard, a major arterial that closely parallels the 405

The same challenges...only bigger

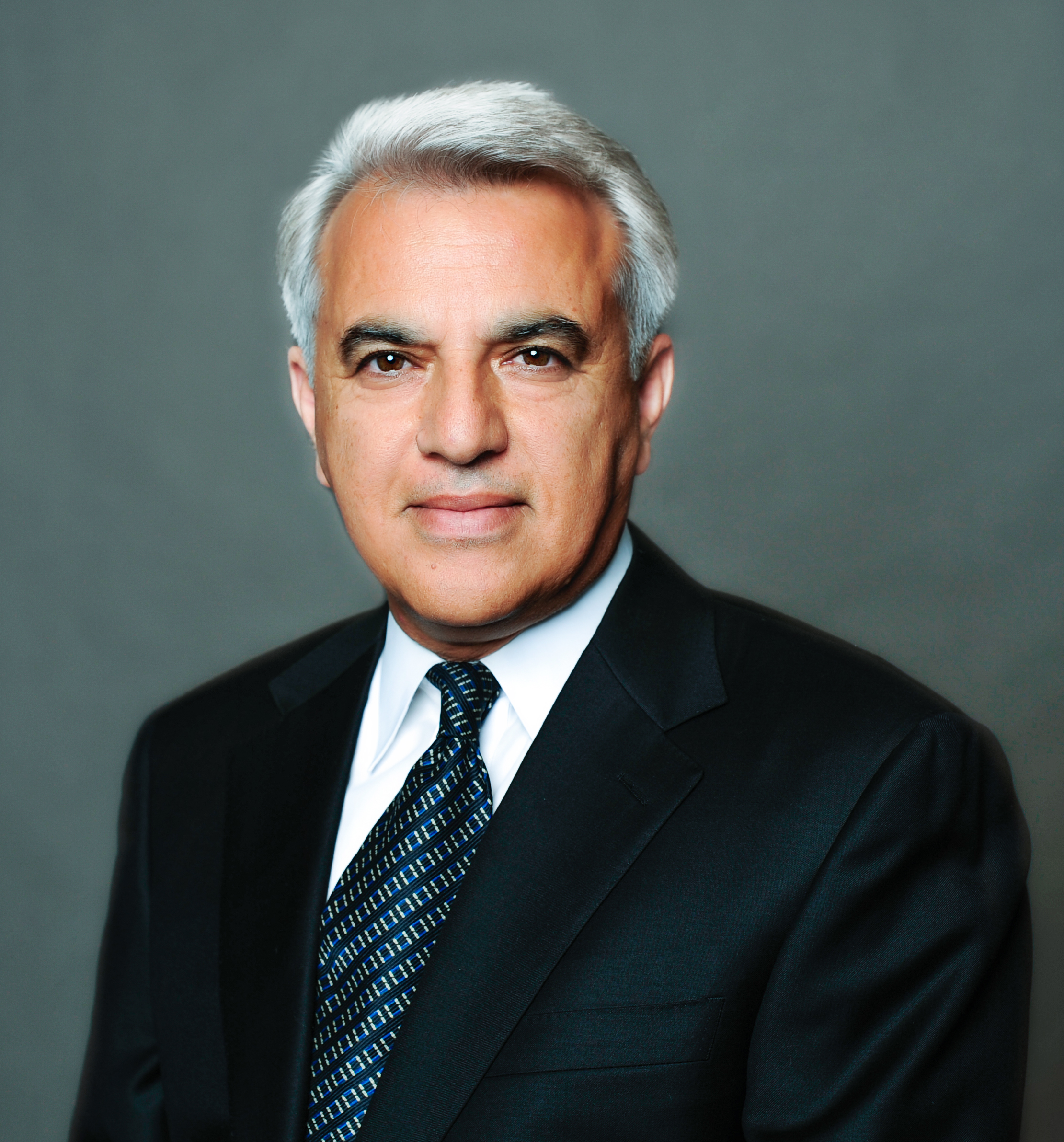

“Widening the mega interstate presented the same challenges any highway expansion and improvement program would, but on steroids,” said Aamir Durrani, HNTB project manager. “This project has a massive traffic management component, and because it is an existing corridor, multiple agencies must be engaged. We also have to factor in existing structures, their modifications and the utilities that will be impacted. And, we must accomplish it all on a compressed timeframe and often in real time.”

“As the design progressed, the integration of state and local facilities became complicated with several competing interests involved in making decisions,” said HNTB’s Joe Quitter, who oversaw maintenance of traffic design at the outset of the project. “Working with Kiewit and Metro to bring together multiple agencies became the path to obtaining approvals.

“Early coordination with construction managers and schedulers was critical in developing efficient, cost-effective staging schemes that were compatible with compliant traffic handling plans,” Quitter said. “The four-dimensional nature of construction sequencing makes design- build an ideal delivery method for maintenance of traffic design.”

Compounding the problem was the freeway’s bare-minimum lane and shoulder widths, which left little room for construction staging and maintenance of traffic operations.

“Overcoming those challenges takes a structured approach and the combined power of everyone involved,” Durrani said. “We know that no matter what challenges come along, our team has the resources to handle it.”

No miscommunication, no lag time

For logistical reasons, the design-build team divided the 10-mile project into three main segments and seven sub areas, but to minimize impact to the community, they tackled all three segments simultaneously.

“Engineering is a people business,” Durrani said. “Since day one, our goal has been to reduce impacts to the surrounding communities and businesses and to people’s daily lives.”

With an improvement project of this magnitude, the design-build team knew coordination would be the key to successful delivery.

“What’s happening in segment one needs to be communicated and conveyed to segments two and three to ensure there are no design discrepancies or duplication of design effort,” Durrani said.

To enhance communication and coordination among the extended project team, the design-builder employed numerous best practices, including:

- Establishing an integrated project office, where members of HNTB, Kiewit, Caltrans, Metro, the City of Los Angeles, subconsultants and utility agencies came together to speed communication by working face-to-face in real time. All total, there were more than 150 people occupying two floors. As a result, communication was improved and facilitated flow of ideas

- Holding over-the-shoulder meetings with Metro and Caltrans throughout design.

- "The clients got to see in real time how the designs evolved and why they had to evolve,” Durrani said. “When you work that way over time, the process becomes smoother and faster because the client has developed a trust in how you work.”

LiDAR condenses survey time

HNTB’s use of mobile LiDAR (Light Detection and Ranging) greatly condensed survey work along the 10-mile stretch, improving safety, saving time and money and requiring little maintenance of traffic.

“We were able to survey the area in 12 hours over three nights,” said HNTB’s Paul DiGiacobbe, HNTB senior technologist. “The conventional method would have taken a month or longer.”

LiDAR uses optical remote sensing devices mounted

on a vehicle to capture data on existing terrain and surroundings while driving

at or near posted speeds. Sophisticated gPS navigation allows the data to be projected onto any project coordinate system with survey-grade accuracy.

Acceleration and accuracy are compatible

HNTB’s scope of work includes the design of earthwork, drainage, utilities, bridges, intelligent transportation systems, traffic signals, freeway and street lighting, signing, striping, retaining walls, sound walls, landscaping, irrigation and maintenance of traffic.

Throughout the project, HNTB has kept pace with Kiewit and the partnering agencies. According to Durrani, sometimes that meant resolving field issues in real time at 2 a.m. or flying to Sacramento to expedite approval with Caltrans.

“We worked closely with the contractor and their schedule,” Durrani said. “To achieve transparency of work effort on critical tasks, we used micro-schedules that were shared with the contractor at the onset.”

Getting bridges in the air

One of the many areas in which HNTB excelled in expediting the project schedule was bridge design. HNTB helped its partner accelerate erection of three well-known and well-traveled bridges: the Mulholland Drive Bridge, the Sunset Boulevard Bridge and the Skirball Bridge.

Eliminating falsework over traffic and employing innovative technologies, HNTB helped its partner get the Sunset and Skirball bridge girder erection completed in unprecedented timeframes.

HNTB delivered its redesign of the Mulholland Drive Bridge in less than three weeks, beating the already-condensed timeline by as much as four months to help Kiewit stay on schedule, and then went on to help accelerate erection by creating enhanced electronic bridge deck 4-scales.

With enhanced electronic 4-scales, Kiewit could apply tailor-made bridge deck elevations to its Digital Terrain Model surfaces, which then were loaded into the contractor’s computers and construction equipment.

“Kiewit was able to make advances in its survey processes during bridge construction, which, in turn, minimized downtime, improved quality and reduced costs,” Durrani said.

In another situation along the 10-mile route, the challenge was to reconstruct two Wilshire Boulevard ramps within 90 days.

“The existing foundation piles were battered in multiple directions on a curved alignment, which made traditional two-dimensional conflict checks difficult,” Durrani said.

HNTB contributed to successful delivery of the new ramp by creating full 3-D models of all existing piles and proposed piles and using those models to identify potential conflicts. HNTB then created contingency plans to address all potential conflicts prior to Kiewit’s field work.

405 by the numbers

- 107 retaining walls

- 27 sound walls

- 26 bridges

- 110,000 cubic yards of cast-in-place concrete

- 900,000 cubic yards of excavation

- 600,000 cubic yards of backfill/embankment

- 86,000 linear feet of bridge piling

No project too large

While the Los Angeles metropolitan area stands to gain a greatly improved asset — one that offers motorists greater safety and mobility, the industry stands to gain yet another case study in using design- build to deliver massive transportation projects.

“U.S. transportation infrastructure is in critical need of improvement,” Durrani said. “The I-405 Sepulveda Pass Improvements Project proves we can tackle even the largest of assets in the largest of cities.”

Saving L.A. from Carmageddon

To accommodate a wider I-405, the Mulholland Drive overcrossing had to be replaced with a longer span, requiring a full freeway closure for demolition. Beginning Friday evening, July 15, 2012, a 10-mile section of the 405 was completely closed for an extended weekend.

The warnings leading up to the shutdown of the 405 were loud and clear, promising motorists that chose to brave the roads may be stuck in traffic for days.

“Carmageddon”— the largest and most complex freeway shutdown in the history of Los Angeles— would affect an estimated 500,000 vehicles. Those motorists would be forced to use other freeways and already-saturated arterials in an area encompassing four counties.

Fearing severe gridlock, officials warned Angelinos to “stay home or stay away,” claiming traffic could back up for 64 miles. But the mother of traffic jams never happened. Dynamic freeway operations maps at Caltrans’ traffic management center stayed green the entire weekend.

“The public awareness and motorist information campaigns— key components in HNTB’s Transportation Management Plan— resulted in greatly reduced traffic in the project area,” explained Joe Quitter, who led HNTB’s Carmageddon effort. “By implementing strategies detailed in the plan, we were able to reach the public to influence them to plan ahead or simply not to drive in L.A. during the shutdown.” A dedicated team of HNTB transportation planners and civil engineers developed the Carmageddon plan on a compressed timetable due to a construction schedule change. Thanks to HNTB’s effort to develop and communicate the transportation management plan:

• Regional highway trips were suppressed by 8 to 12 percent

• Northbound and southbound I-405 traffic approaching the closure was diverted by up to 60 percent

• Adjacent highway trips were reduced by 40 to 60 percent

• Vehicle backups were minimized to less than one mile

In addition to designing the bridge’s replacement, HNTB provided on-site engineering services during the demolition operations, which were completed 17 hours ahead of schedule.

“The Mulholland Bridge demolition was a major operation within a billion-dollar freeway-widening project,” explained Quitter. “The successful closure provides a national — if not international — template for the planning and design of major road closures and is a testament to the design-build delivery method.”

SEE MORE ARTICLES

MORE DESIGNER STORIES

INDYGO RED LINE

CASEY ARBORWAY

ALLEGIANT STADIUM

ORLANDO INTERNATIONAL AIRPORT, SOUTH TERMINAL

US 290 Program