Maximizing value using a Progressive Design-Build model

Collaborative contracting models have evolved over the last several years and are becoming more common for transportation projects. One model, progressive design-build (PDB) has emerged recently, with many owners applying it to their programs. While PDB and other forms of collaborative contracts have the potential to deliver beneficial solutions through early contractor involvement, certain steps are critical for owners to realize the benefits.

By Jonathan Startin and Kevin Phelps | HNTB

In recent years, an increase in project backlogs and market uncertainty has made it more challenging to attract fixed-price bids, particularly for large, complex transportation projects. As a result, many owners have turned to delivery models with quality-dominated selection (see Figure 1). These collaborative models, in which an initial phase is awarded before price and schedule have been agreed, are becoming more common in the U.S. transportation industry.

(DB)

(DBB)

(D2B2)

(PDB)

PDB and other collaborative delivery models like CMAR / CMGC promote early contractor involvement, enabling owners and their partners to jointly identify, manage and optimally allocate risks while fostering innovation through an open-book, collaborative design process. These features can improve cost certainty, schedule performance and project outcomes.

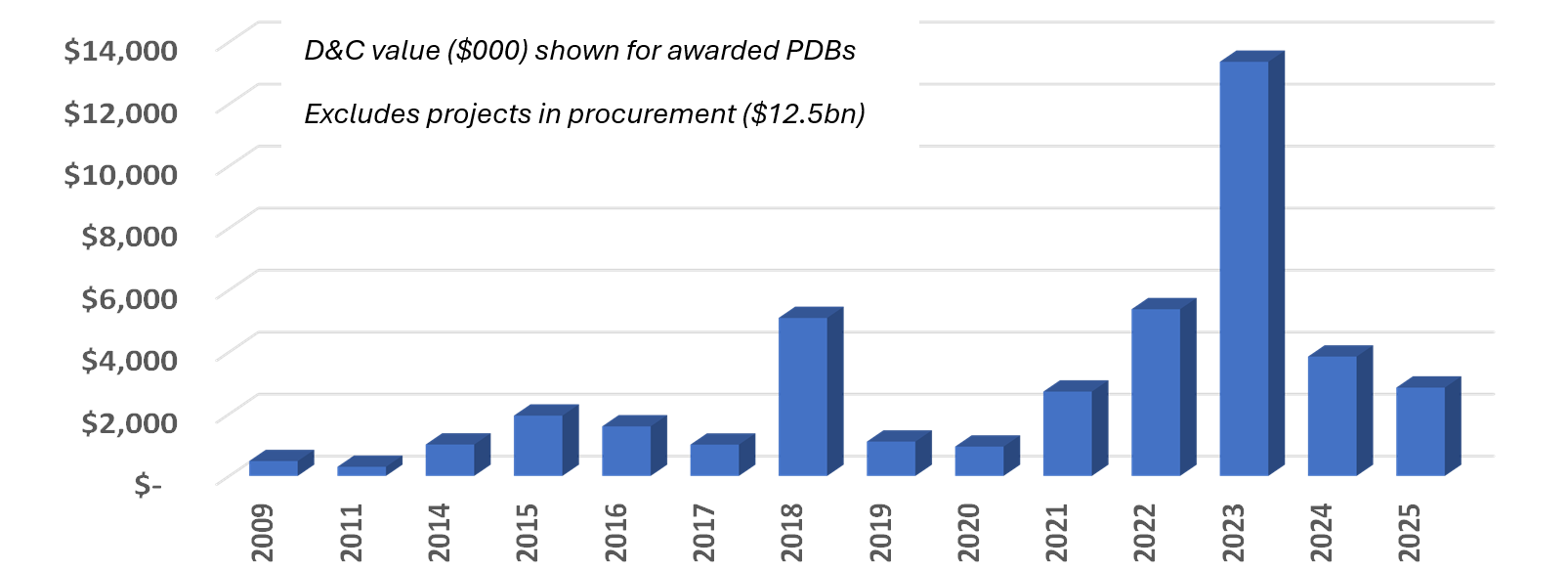

The appeal and availability of PDB are growing rapidly with owners favoring the single contract structure, similar to traditional design-build, rather than the owner employing the designer separately. Enabling legislation is becoming more common, and only a few states restrict the use of PDB through legislation. A recent analysis by HNTB on nearly 100 projects confirmed that in the past 15 years, there has been a notable increase in the total value of projects delivered through PDB across highway, rail, transit and bridge sectors (see Figure 2).

Success for PDB depends on organizational readiness, strong technical and commercial acumen, negotiating skills and informed decision-making. Key decisions include selecting the right delivery method for each project, managing pricing transparency, risk allocation and alignment of project goals. When supported by a structured, informed strategy, and the appropriate resources to manage an involved and sophisticated process, PDB can help agencies identify optimal solutions and deliver projects that might otherwise place significant strain on time and budget under more traditional delivery models.

Figure 2: Value of PDBs awarded by year

Key considerations for collaborative delivery

Achieving an agreed-upon price and schedule in a PDB model depends on a range of strategic considerations that shape how owners and contractors work together throughout the project. While grounded in PDB, these considerations reflect lessons common to many collaborative delivery methods and can guide decisions for other models as well.

1.) Optimize the delivery method selection process

A robust process is needed to match projects with the right delivery method. That process should be standardized across an owner’s program. PDB is best suited to complex projects for which the owner has not yet fully defined a solution and collaboration can help tailor the design and scope to suit price and schedule constraints.

2.) Start small to build sustainable programs

Starting with smaller projects that offer enough complexity to benefit from a collaborative approach can help lead to sustainable collaborative contracting programs. These early efforts lead to key lessons learned and create a foundation for future, larger-scale and higher risk projects. This helps support screening of future projects for their suitability for PDB, among other key take aways.

3.) Develop transparent partnerships

Project success requires both the owner and the contractor to understand and adhere to principles of openness and trust. Attributes of a PDB partner that owners should consider evaluating as part of the procurement include:

- A transparent approach to sharing pricing assumptions and benchmarks

- An open and collaborative approach to risk pricing, with fair and effective assessment of ties between risk allocation and cost control

- A demonstrated history of successful, collaborative price agreement with owners, their consultants, and other stakeholders.

4.) Establish clear “stage gates” and structured pricing and reconciliation process

The PDB contract should clearly define the required price submittals, the sequence of and approach to price reconciliation, and the owner’s review timelines. Adopting formal stage gates between the PDB phases helps proactively manage the transition from early cost estimates to the Guaranteed Maximum Price (GMP), maintaining alignment and avoiding surprises. Requiring justification for upward trends between estimates and before advancing to the next stage gate fosters collaborative problem-solving and ensures decisions remain grounded in shared goals.

5.) Sustain a strong owner-side negotiating position through the project’s phases

Using an “off-ramp,” which results in ending the contract before a final price is set, isn’t a failure. It’s a valid option when price or schedule issues can’t be resolved. Owners should develop a definitive off-ramp process and update throughout the preconstruction phase as facts on the ground evolve. This includes outlining alternative contract options and when to use them to stay on track. Having a backup plan helps maintain leverage during negotiations.

6.) Use the risk register as a key management tool

Under PDB, the risk register becomes a vital tool for aligning expectations, informing contingency values and maintaining transparency. Owners benefit from having risk specialists who understand how contractors approach pricing and can engage as informed partners, helping to surface embedded assumptions and ensure that risks are allocated and accounted for appropriately.

Realizing the full value of collaborative delivery

By selecting the right projects, building internal capabilities, establishing clear expectations around pricing and risk and fostering transparency throughout the process, owners can navigate the complexities of PDB delivery with greater confidence. These practices position agencies to control costs, accelerate delivery and strengthen collaboration, turning the potential of PDB into tangible project results.

ABOUT THE AUTHORS

Kevin Phelps

Director, Advisory

HNTB Corporation

Phelps is an experienced program director, including strategic planning, management, scheduling and budgeting. Phelps has led market and industry outreach efforts pre-solicitation, conducted market analysis and market data subject matter expert input throughout solicitation process. Phelps has extensive knowledge of project packaging, delivery method analysis, and procurement process including alternative delivery/collaborative contracting (CMAR/CMGC, Progressive Design-Build, Design-Build, Delivery Partner, Public-Private Partnerships).

Jonathan Startin

Jonathan Startin

Senior Project Director

HNTB Corporation

Startin has more than 30 years of experience leading technical and commercial procurement and contracts with a focus on innovative delivery, including public-private partnerships (P3s) and progressive design build in transit, rail, bridges, highways and aviation. Startin has provided technical advice to transportation clients on alternative delivery across the country.